Welcome to CivilGEO Knowledge Base

Welcome to CivilGEO Knowledge Base

Welcome to CivilGEO Knowledge Base

Welcome to CivilGEO Knowledge Base

The structural choice of a culvert and corresponding inlet is based on environmental considerations, risk to property, cost of construction and maintenance and also aesthetic considerations. The capacity of an existing culvert can be increased with an improved inlet.

An improved inlet serves to funnel the flow into the culvert to remove the point of control from the face of the inlet to a throat located downstream from the face. The normal contraction of flow is included in the transition from the face to the throat. An improved inlet may be economical if the culvert is operating under inlet control, but not if the culvert is operating under outlet control.

An improved inlet may offer the advantage of increasing the capacity of an existing culvert that has become inadequate because of changes in the watershed which have increased the discharge to the culvert. However, improving a culvert inlet is not recommended in the following situations:

Careful consideration should be given before selecting and using an improved inlet design. Guidelines for design can be found in FHWA publication, Hydraulic Design of Highway Culverts, HDS-5.

The recommended types of improved inlets are top-tapered inlets, side-tapered inlets, and slope-tapered inlets.

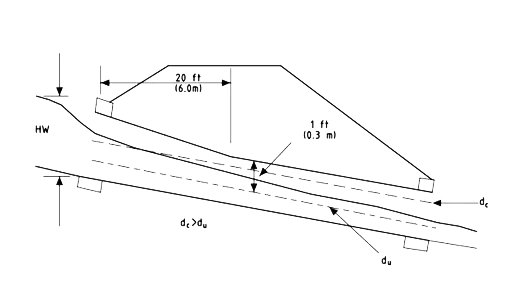

A simple transition of depth in a rectangular box culvert may improve the hydraulic efficiency. If the box culvert is operating under inlet control, the barrel of the culvert is more hydraulically efficient than the entrance geometry. The designer may reduce the barrel depth in transition from the original depth to a minimum of 1.0 feet (0.3 m) greater than the uniform depth of flow. The transition length should be a minimum of 20 feet (6 m) as shown in Figure 1, below. This method is arbitrary, and care should be exercised when the culvert is operating in inlet control.

In terms of design and construction, top-tapered transition inlet is effective, economical, and simple to construct. This type inlet improvement is desirable when designing a multiple barrel box culvert. Other inlet improvement types are not feasible for multiple barrel box culverts because of the need to taper or flare the sidewalls of the barrels.

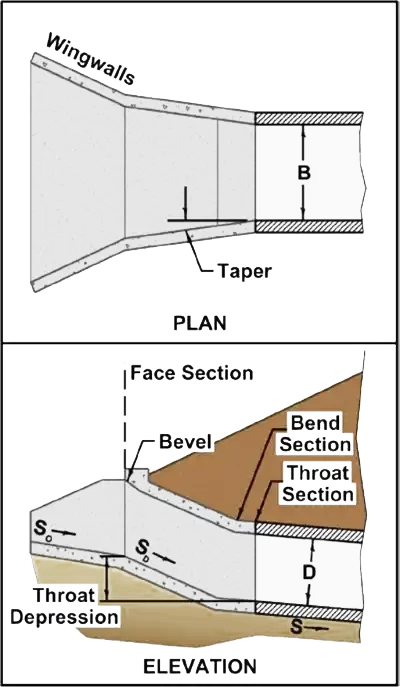

Side-tapered inlets involve a widening of the face area of the culvert by tapering the sidewalls. Such inlets have two possible control sections as shown in : the face and the throat as shown in Figure 2. Maintain control at the throat for the design discharge in order to realize significant cost savings in the culvert barrel. This type of improvement is similar in operation to the flared inlet for pipes.

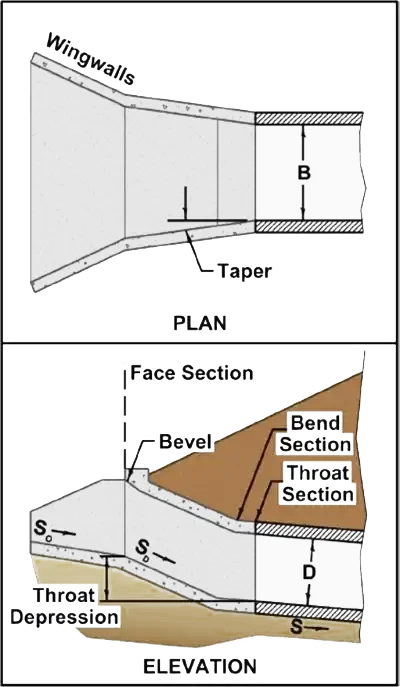

The slope-tapered inlet incorporates the efficient flow characteristics of side-tapered inlets with a concentration of more of the total available culvert fall at the throat control section. Figure 3 shows a slope-tapered inlet. Generally, slope-tapered improvements are not practical for pipe culverts because of their complexity.

Some of the drawbacks of slope-tapered inlets are as follows:

1-800-301-02-955

1-800-301-02-955

608-729-5100

608-729-5100

(US and Canada)

[email protected]

[email protected]

+1 608-729-5100

+1 608-729-5100

CivilGEO India

Graphix Tower, A-13 A

3rd Floor, Sector 62

Noida, Uttar Pradesh 201309

IndiaTel:

1-800-301-02-955 or

+91 022-3831-8601

CivilGEO United States

8383 Greenway Blvd

6th Floor

Middleton, WI 53562

USATel:

608-729-5100 or

800-488-4110

Copyright © CivilGEO, Inc. All rights reserved. The CivilGEO logo, “GeoHECHMS”, “GeoHECRAS”, and “Ready To Engineer” are registered trademarks of CivilGEO,

Inc. All other brands, company names, product names or trademarks belong to their respective holders.

We use cookies to give you the best online experience. By agreeing you accept the use of cookies in accordance with our cookie policy.

When you visit any web site, it may store or retrieve information on your browser, mostly in the form of cookies. Control your personal Cookie Services here.

The ZoomInfo WebSights snippet drops three cookies to track Unique Visits:

1. _pxhd - Related to the Perimeter X security layer (Perimeter X isused to prevent bot attacks).

2. _cfduid - Related to the CloudFlare security layer (CloudFlare is the Network Security protocol that ZoomInfo uses to orchestrate the rate limiting rules).

3. visitorId - This is how WebSights identifies recurring visitors